Microwave Test Facility

We have an several industrial microwave generators on-site that allow us to do advanced feasibility, quality and economic studies.These studies can usually estimate exhaust needs, power usage and cost per pound water removed or product produced as well as other useful calculated data.

Microwave Test Systems

- conveyor belt industrial microwave dryer

- 1-75 kilowatts

- 10 foot stainless steel oven

- 40 inch wide polypropylene belt

- Product temps up to 280 F

- 2-30 feet per minute belt speed to simulate high throughput conditions

- variable 2500 CFM exhaust system

- highly instrumented to aid in quantitative analysis of test runs

- custom water ballast system which allows us to run small samples

- 50 kilowatt L-band solid-state generator, PTL-50

- pulsed, variable frequency, exact power

- 2.5 kilowatt L-band solid-state generator, PTL 2.5

- pulsed, variable frequency, exact power

- 1 kilowatt S-band solid-state generator, PTS-1

- pulsed, variable frequency, exact power

- 4 kilowatt S-band solid-state generator, PTS-4

- high temperature applicator

- allows us to heat samples up to 1800 F (1000 C)

- ceramic crucible

- inert gas, vacuum or atmosphere

Advanced Instrumentation

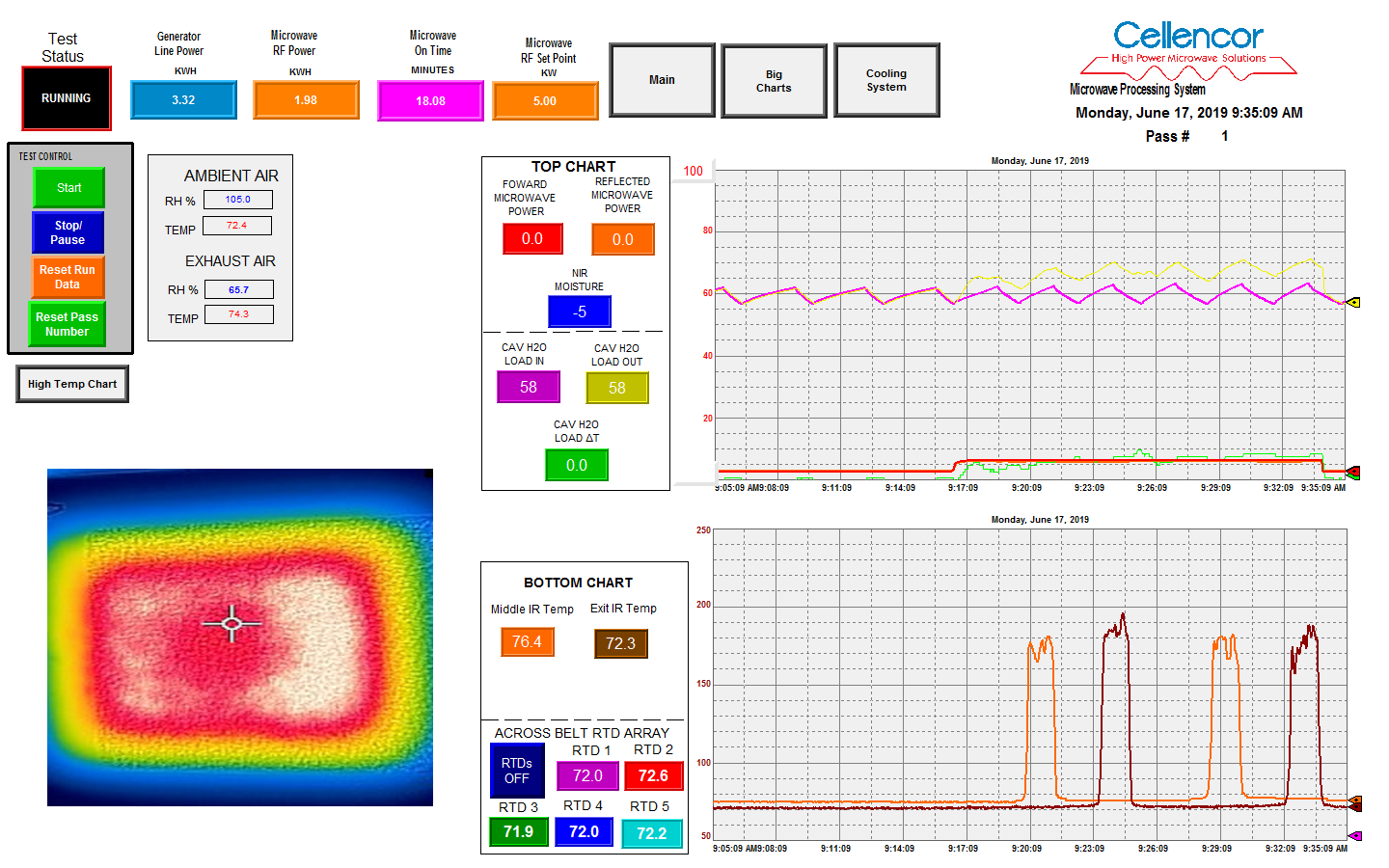

Our test systems are very highly instrumented to help us understand how the product is reacting to microwaves so we can better plan and optimize potential equipment. These tools can also prove critical to help us fine tune the settings of the system to maximize efficiency.

- IR temperature sensors

- NIR moisture analyzer

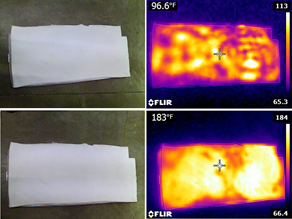

- thermal imaging cameras

- spectrometer

- directional couplers to measure forward and reflected microwave energy

- sensitive ammeters to measure total power consumption

- RTD's to measure product temperature exiting the microwave

- thermometers and hygrometers to measure ambient air temperature and humidity

- flowmeters to measure cooling

- ananometers to measure CFM of the exhaust

- HD camera inside the microwave oven to show real-time video of how the material react

Software and Record ing

ing

- proprietary software for displaying test data

- data is displayed in real-time on an HD monitor so customers can see instant results

- all data from each test run is logged in a CSV file for easy data recovery

- this data is often used to create reports and presentations which can be used to make business decisions about purchasing

- cellencor's proprietary microwave power calculator- allows us to know exactly how much equipment your process needs

Wet Lab

- Refrigerator and deep freezer to store large quantities of testing material (up to 20 gallons or 200 pounds)

- halogen moisture analyzers

- centrifuges

- microscopes allow us to analyze product quality down to micron level

- pH meter and viscosity meters

- convection lab oven allows us to get very accurate moisture levels

- micro-balance (.001g accuracy up to 50g)

- industrial floor scale (.2 pound accuracy up to 1000 lb)

- various glass labware

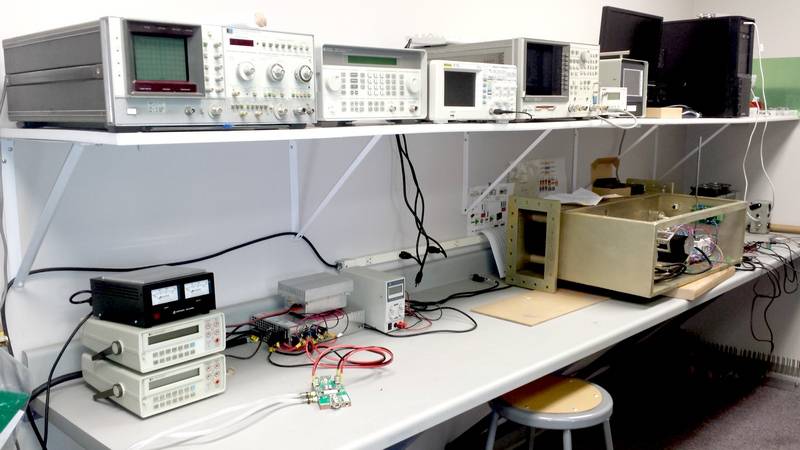

RF Electronics Lab

Cellencor also has an onsite electronics lab that allows up to build and test new products such as high power patch antennas.

- vector network analyzers

- spectrum analyzers

- oscilloscopes

- signal generators

- power meters

- frequency counters

Fabrication Shop

Cellencor also has a small onsite fabrication shop where we can do custom machining work for R&D applications.

- CNC mill

- lathe

- router

- welder

- plasma cutter

- laser engraver

- reflow oven

- forklift