Drying

What is Drying?

What is Drying?

Drying is a mass transfer process consisting of the removal of water or another solvent by evaporation from a solid, semi-solid or liquid. Drying typically removes water, but some other common solvents include oils, VOC's, and alcohols. Rapid drying is typically performed by heating the material up to the solvents boiling point.

Why are Microwaves used for Drying?

Microwave drying uses high frequency radio waves to heat and dry various materials. Microwave heating is fast, efficient, and can produce superior quality results compared to other heating methods. Microwave drying makes up a large percentage of our microwave applications primarily because it works so well and is a proven technology. Some key benefits to microwave drying include but are not limited to:

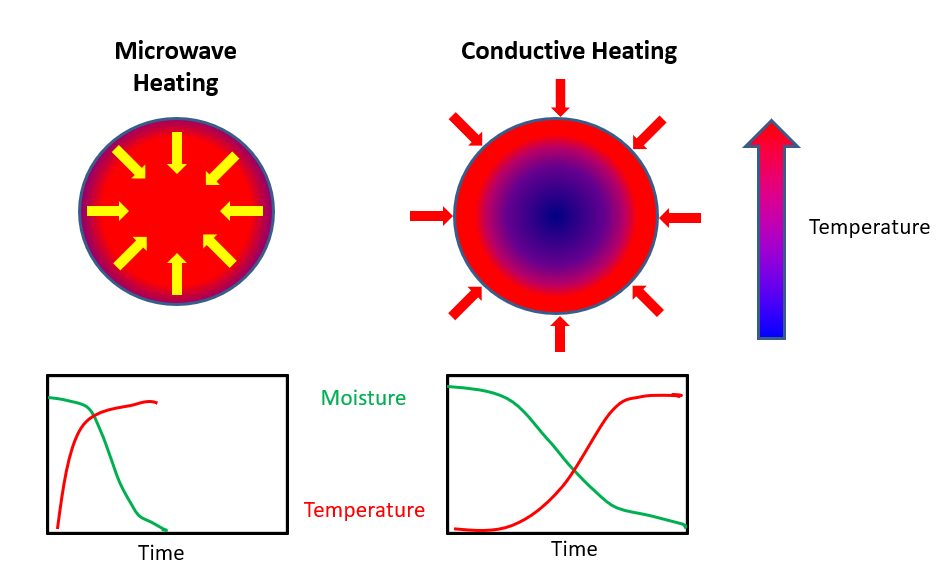

- Microwaves penetrate deep into product bed and preferentially couple with the water molecules to help drive out internal moisture.

- Speed: higher throughput than any almost any other type of heating due to volumetrically heating the material instead of relying on conduction from hot air.

- Gentle, low temperature drying. Products often do not exceed 140 F (60 C) due to surface evaporative cooling effects.

- Produces superior quality and highly consistent product.

- Precise temperature and drying rate control.

- Clean – typically no emissions, no permitting.

- Efficient: little energy wasted heating air, exterior walls and belts.

- Some commonly dried products: Food stuffs, Agricultural products, Botanicals and Herbs, Animal feeds, Ceramics, Large fiber filters, Metal Casting Molds, Algae for Biofuels, Carbon composite materials, Polymer Powders, Woven Filters and Insulation, Corn Ethanol By-Products, Aquaculture Feeds, Graphene and Lithium.

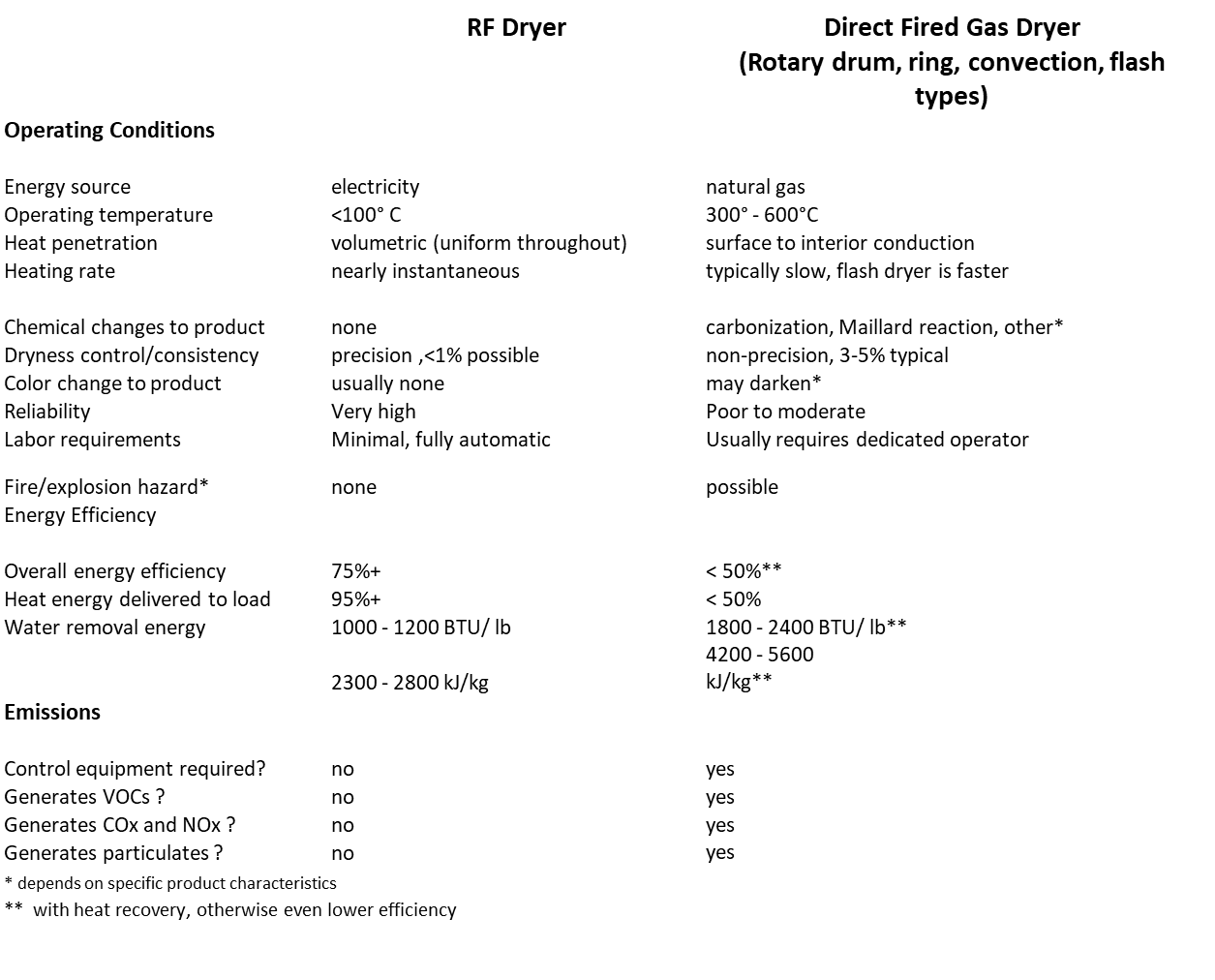

Microwave VS Gas Dryer Comparison